Portable GC, Portable GC System, Portable GC Analyzer, Portable Gas Chromatograph, Portable Gas Chromatography, Mobile GC, Mobil GC, Mobile GC System, Mobile Gas Chromatograph, Companion Portable GC, Companion 1 GC, Field Portable GC, Field Portable Gas Chromatograph

Companion 1 Portable GC - It goes with you Anywhere!

Companion 1 - GC Features

-

Modular Design – Built-in Accessories

-

Many Standard Application Specific Configurations

-

Compact Oven and Soft Landing

-

Color Touch Screen Instrument Control

-

Free standing operation with on-board GC Methods

-

Proprietary Digital Signal Processing

-

Built-in Instrument Diagnostics

-

Only 1 detector (FID, NPD, PID, TID)

-

1, or 2 Injectors (on-Column, or Custom S/S)

-

Temperature Control to 0.001°C

-

Temperature Program with Multiple Ramps

-

EPC Pressure Control to 0.001 kPa

-

EPC Pressure Control of all Gases

-

Ambient to 325°C Column Oven

-

Up to 80°C per/min Column Oven Ramp

-

Fast Cooldown 325°C to 50°C in < 4 min

-

Compact and Lightweight

-

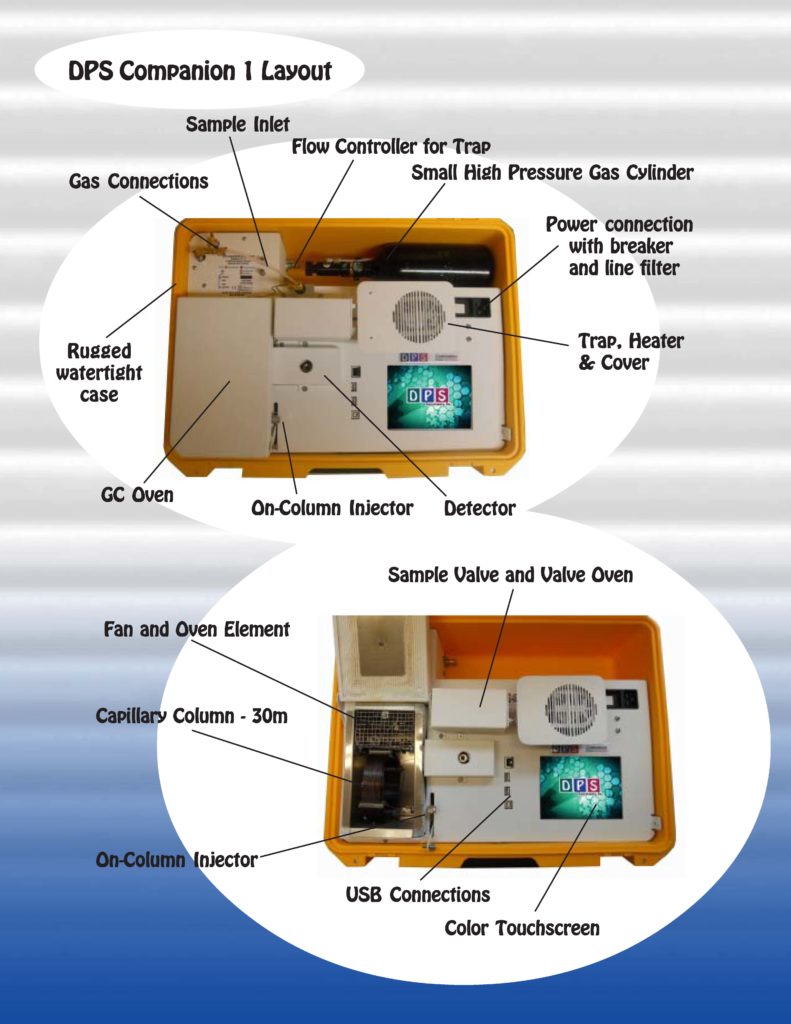

Water Tight Carrying Case (52 x 40 x 21 cm)

-

Approximately 10 kg

-

1 or 2 compact gas tanks, sold separately

Custom Built-in - Accessories

Air Concentrator –

The built-in air concentrator in the Companion 1 Portable GC provides both a compact portable sample concentrator and a shortest possible sample path. Heated valve and sample lines create an inert sample path. The sample trap is plumbed in a true backflush fashion. We can equip the sample trap with a variety of packing materials. This offers the chance to achieve the best concentration of the compounds you want to analyze. A built-in vacuum pump loads the sample and a variable flow controller provides consistent sample trapping. The Timeline of the DPS Control Software automates the entire sequence of the Air Sample Concentrator for the analysis of one sample. Or the system can be set up to run unattended 24/7, collecting and analyzing samples every hour, or so.

Load – The vacuum pump draws the sample from the inlet through the Trap and then to the flow controller and pump to limit any possible cross contamination between samples.

Inject – The carrier gas sweeps the components from the trap to the analytical column.

Headspace Concentrator –

The built-in Headspace Concentrator in the Companion 1 Portable GC provide the shortest possible sample path. The Sample Vial is heated and then consistently Pressurized before loading the Sample Loop. A fixed Sample Loop ensures reproducible sampling and the sample lines are Flushed between analyses to limit any cross over contamination. The Timeline of the DPS Control Software automates the entire sequence of the Headspace Concentrator for the analysis of one sample at a time.

Automated Timeline – In the 1st sequence the carrier gas is diverted to Flush out the Sample Lines. The Sample Probe is then inserted into the Headspace Vial. During the 2nd step the carrier gas flows to the analytical column. The Vial Heater heats the Headspace Vial and allowes it to equilibrate. During the 3rd step the Headspace Vial is pressurized for a few seconds. In the 4th step the sample is loaded onto the Sample Loop by releasing the pressure in the headspace vial. In the 5th step the Sample Valve rotates to the ON position and the carrier gas sweeps the components from the Sample Loop onto the analytical column.

Purge & Trap Concentrator –

The built-in Purge & Trap Concentrator in the Companion 1 Portable GC has the same Trap features as the Air Concentrator. The water sample is purged with inert gas to extract the sample compounds and load them onto the Trap. A variable flow controller regulates the Purge Gas for consistent sample trapping. The Timeline of the DPS Control Software automates the entire sequence of the Purge & Trap Concentrator for the analysis of one sample at a time.

Load – The Purge Valve turns ON to start the stream of gas flowing to the Purge Vial. With this configuration the flow controller is up stream from the Trap to limit any possible cross contamination between samples.

Inject – The carrier gas sweeps the components from the trap to the analytical column. With the Purge Valve OFF there is no flow through the other side of the valve. The Purge Valve can be turned ON to blow out the sample lines using a blank Vial.

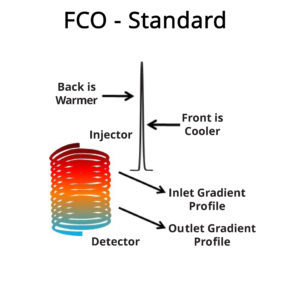

Fluidless Column Oven (FCO) for Companion 1 Portable GC

In the Standard model a series of Inlet and Outlet heaters place a steady state temperature profile right on the analytical column. The analytical column is connected to the GC injection port as usual. The injected sample passes into the Inlet half of the Analytical Column. Because of the negative gradient profile the peaks sharpen as they travel through the column. The peaks sharpen naturally, because the front of the peak is always a little cooler than the back of the peak. The Outlet half of the column also has a negative gradient profile. So it sharpens the peaks further, before they pass to the detector. The Inlet and Outlet temperature profiles are set independently. You can easily adjust the profiles to analyze many classes of compounds.

Companion 1 GC - Specifications

Electronics Module:

-

Enter and store GC Methods via Color Touch Screen

-

Actual and set-point display of all GC parameters

-

Safety Limits on all user entered parameters

-

Oven Temperature Programs (OTP) with Multiple Ramps

-

Pressure Programs for Carrier Gases with Multiple Ramps

-

Timeline for sequencing Relays and Valve

-

Detector Control of all Parameters on one page

-

Electronic Pressure Controllers (EPC’s):

-

Atmospheric Pressure & Temperature Compensation

-

EPC Pressure Control with 0.1 kPa set-point resolution

-

-

Plug and Play GC Control, Oven, and Detector Board

-

Microprocessor Controlled

-

Proprietary Digital Signal Processing

-

Digital Signal Outputs for each Detector

-

Universal voltage input (85 – 240 Vac) with line filter and breaker.

-

7 amps at 48 Vdc total power consumption

Detectors:

-

1 Installed

-

400°C Temperature Limit with 0.1°C set-point resolution

-

24-bit Digital Outputs for the detector via USB

-

EPC Pressure Control with 0.1 kPa set-point resolution

Available Detectors:

FID – Flame Ionization Detector (100 pg detection limit)

NPD – Nitrogen Phosphorus Detector (20 pg detection limit)

PID – Photoionization Detector (10 pg detection limit)

TID – Thermoionic Detector (20 pg detection limit)

Oven Module:

-

Ambient to 325°C Column Oven

-

Up to 80°C per/min Oven Ramp

-

Fast Cooldown 325°C to 50°C < 4 min

-

200 watt Heater Element

-

12.5 x 10.5 x 12.5 cm area for Packed, or Capillary Columns

-

Multiple Temperature Ramps with 0.1°C set-point resolution

Accessories:

-

Sample Valve – Electronically Actuated

-

Heated Valve Oven

-

Bulit-in Air Compressor

-

Air Concentrator

-

Headspace Concentrator

-

Purge & Trap Concentrator

-

MicroExtractor Concentrator

-

Methanizer

-

Sample Solenoids

-

Vacuum Pump for Sample Inlet

-

High Pressure Tanks & Refill Station

-

Injectors:

-

1 or 2 Installed

-

Cool On-column Injector

-

Heated On-column Injector

-

Heated On-column Split/Splitless Injector

-

Cool Split/Splitless for Gas Samples

-

Multiple Pressure Ramps with 0.1 kPa set-point resolution

-

-

Data Communications:

-

Bi-directional communication with popular Data System

-

Digital Signal Output via USB

-

Network Connectivity:

-

Enterprise Compatible Network GC running Windows XPe

-

Ethernet Connection using Windows Network Protocol

-

On Board ETX Computer for GC Control and Data Acquisition

-

Remote Control of GC and Data Acquisition over LAN