Micro GC, Micro GC System, μ GC, μ Gas Chromatograph, μ TCD, μ TCD GC, μTCD, μTCD detector, Multi channel GC, Micro TCD GC, Micro TCD, micro-machined TCD detector, TCD, TCD detector, Thermal conductivity Detector, channel GC, micro-machined GC

Micro-TCD GC - Lightweight, Versatile & Reliable!

Micro-TCD GC - Features

-

Rugged Micro-TCD Gas Chromatograph

-

1 to 4 GC Column Oven/Micro-TCD Channels

-

2 Micro-machined Thermal Conductivity Detectors (TCD) per Channel

-

Designed for Unattended Continuous Operation

-

Most analyses in less than 1 min

-

Integrated 3-Stream Selector

-

Automated Calibrations

-

Fast & Accurate with Low Maintenance

-

Free standing operation with on-board GC Methods

-

Built-in Instrument Diagnostics

-

Easy Chromatography Data System

-

Temperature Control to 0.001°C

-

Pressure Control to 0.001 kPa

-

Ultra Compact and Lightweight (20 X 15 X 10 cm)

-

Approximately 8 kg

Custom - Components

Micro-TCD GC –

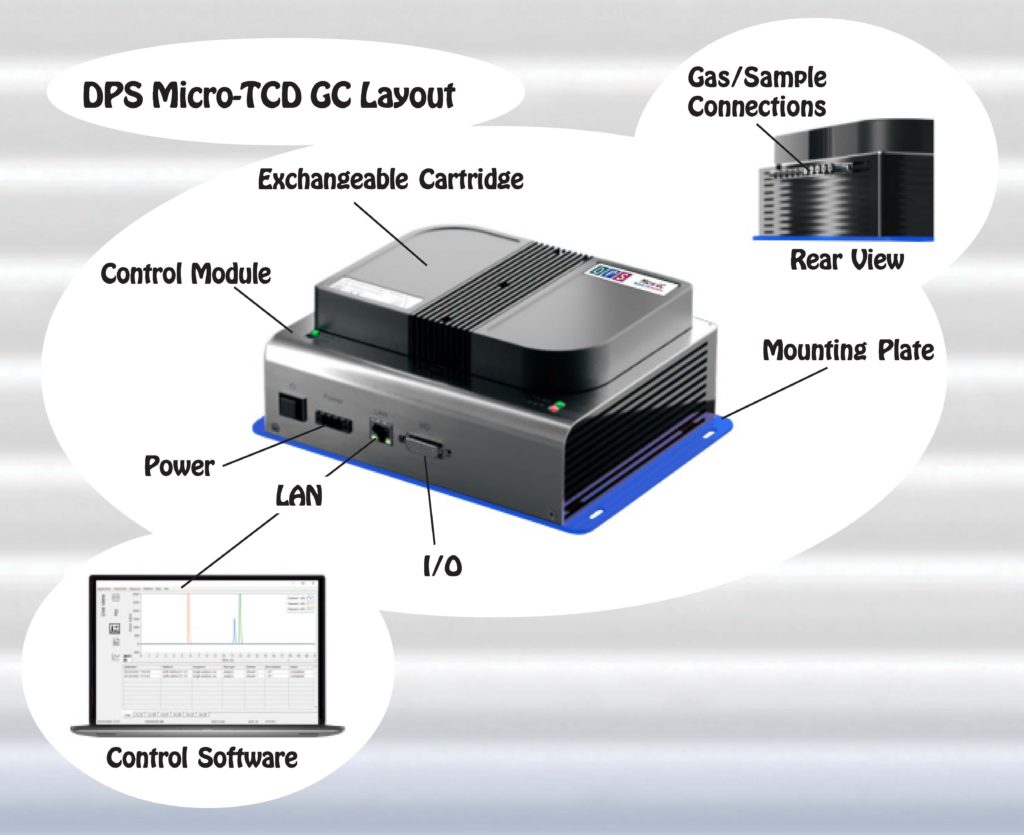

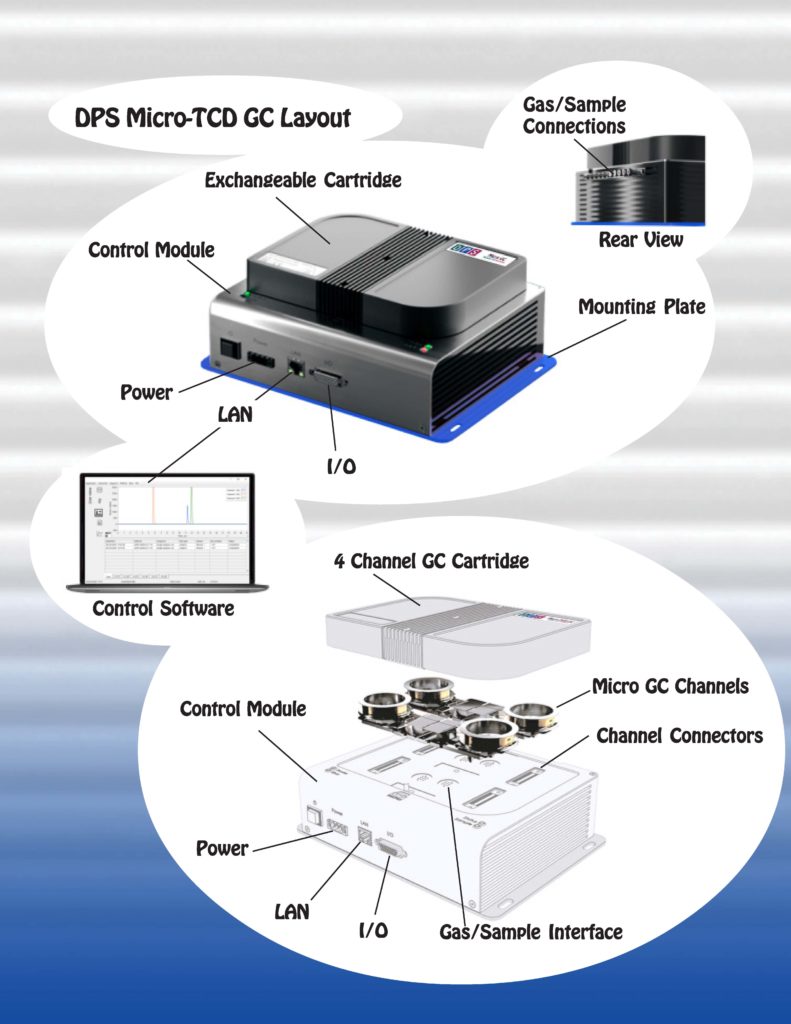

The small, rugged, and versatile DPS Micro-TCD Gas Chromatography Systems, feature a micro-machined Thermal Conductivity Detector (TCD). The DPS Micro-TCD GC can pack 1 to 4 Column Oven/Micro-TCD Channels inside the same Exchangeable cartridge. Each Channel contains a Column Oven, Pre-Column, Analytical Column and 2 Micro-TCD detectors.

In addition, each Channel also connects Injection and Backflush valves offering unattended operation and super-fast analysis times. A built-in Stream Selector automatically loads each sample stream, or calibration gas. Most analyses are completed in seconds and one sample can be injected right after another for Continuous Monitoring applications.

The DPS Micro-TCD GC Systems are a new kind of GC. Offering all of the separation power of our conventional GC System in an ultra-small package, allowing on-line, at-line, or laboratory analyses to be performed almost anywhere. And with 4 Channel capability, even complex analyses can be performed in seconds.

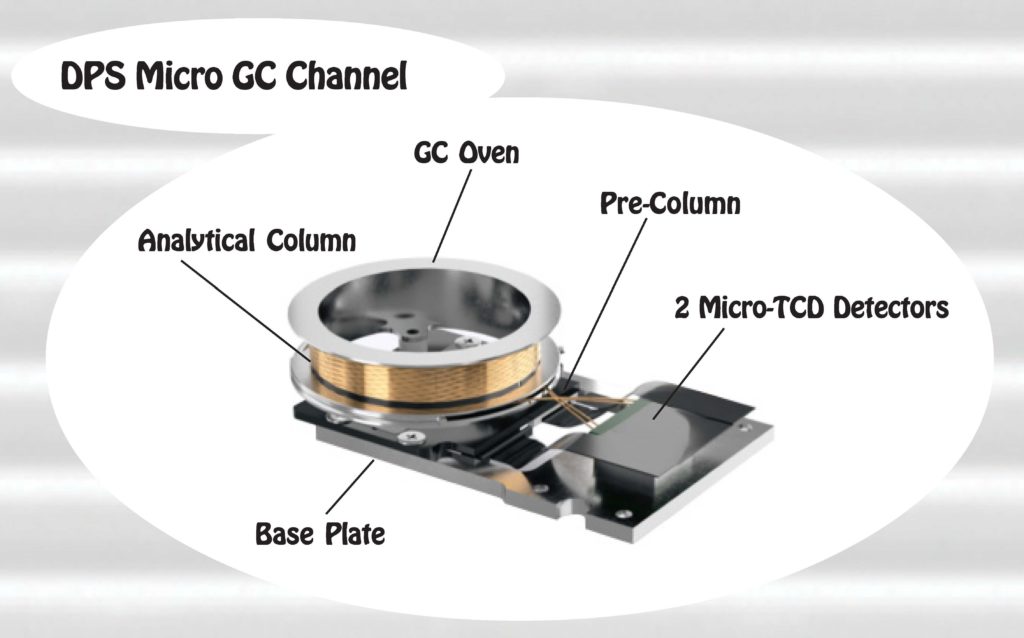

Micro-TCD GC Channel –

Each channel is independent and self-contained. Once mounted inside the cartridge it connects to the control module to provide all of the capabilities of a complete GC system. Including analytical column, pre-column, GC oven, 2 TCD detectors, sample injector, back-flush valve and more.

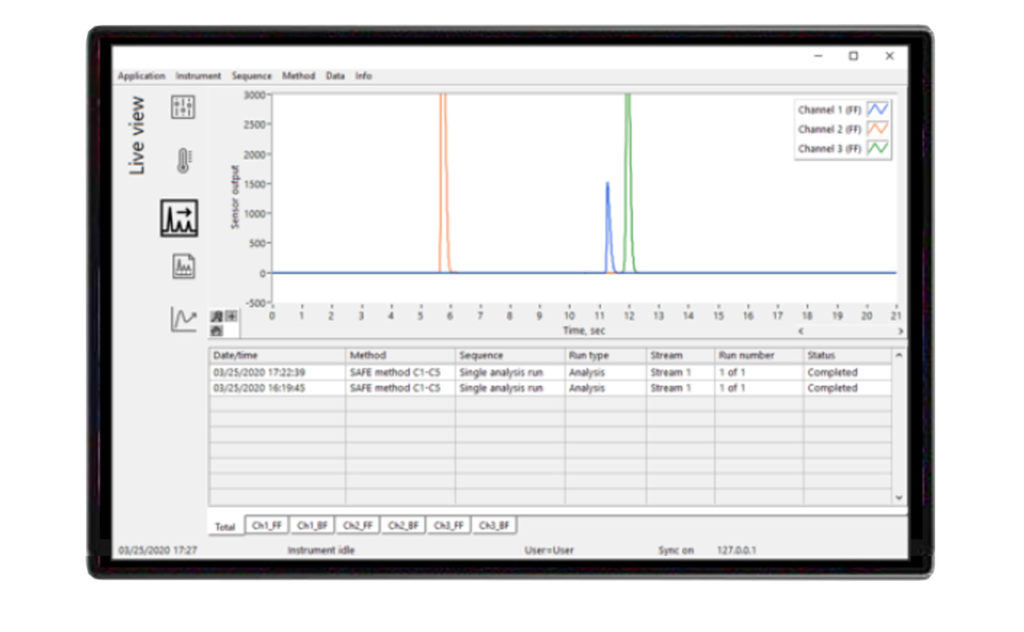

Computer & Chromatography Software –

By connecting a computer you can access the chromatography and control software to edit methods and sequences. These are stored inside the GC, so that when the computer is disconnected the Micro-TCD GC runs unattended sending results out the I/O connections. The data is stored inside the GC as well, so once you connect a computer again you can access it all.

DPS Micro-TCD GC - Specifications

Micro GC Channels:

-

1 – 4 Micro GC Channels in an Exchangeable Cartridge

-

Each GC Channel contains GC Oven, Analytical Column,

Pre-Column, 2 Micro-TCD Detectors, Electronic & Gas

Connectors.

Software/GC Control Interface:

-

1 – 4 Micro GC Channels in an Exchangeable Cartridge

-

Enter and store GC Methods via Computer connection

-

GC Methods run without Computer connection

-

Safety Limits on all user entered parameters

-

Communications: RS232, RS485, Ethernet, Digital I/O

-

Protocols: Modbus, TCP

-

Sequencing for Sampling, Injection, Backflush, etc.

-

Memory Storage – up to 256Gb

-

Control for Carrier Gas(s)

-

Control for Valves (Injection, Backflush, Sample)

-

Schedule Auto-calibration

-

Control for Stream Selection

-

Digital Signal Outputs for each Detector

-

Universal voltage input (85 – 240 Vac, 50-60Hz)

-

Power Supply – (20 – 28 Vdc)

-

Power Consumption – 75 Watts maximum

Control Module:

-

Moisture – (5 to 95 %)

-

Operating Temperature – (5 to 55 oC)

-

Storage Temperature – (-20 to 60 oC)

-

Dimensions – 20 X 15 X 10 cm

-

Weight – 8 Kg

Detectors:

-

1 – 4 Micro-TCD Detectors Installed

-

2 Micro-TCD´s per Channel (8 total)

-

Detection Limits (500ppb – 100%)

-

150 oC Temperature Limit with 0.1 oC set-point resolution

Injectors:

-

1 Micro-machined Injector per Channel

-

Sequence Controlled Injection Time

Columns:

-

1 Pre-Column with Backflush per Channel

-

1 Analytical Column

-

Isothermal Operation

-

Repeatability – < 0.05% RSD

-

Cycle Time (Typical) – 15 – 60 sec

-

Optional Temperature Program

Gas/Sampling:

-

Gas Ports – 1/16″

-

Carrier – Helium, Argon, Nitrogen, or Hydrogen

-

Carrier Input Pressure – 450 kPa

-

Carrier Consumption (Typical) – 15 mls/min

-

Sampling – Pressurized or by internal Vacuum Pump

-

3 Sample Streams (more optional)